To the average onlooker, LSS certifications sound like martial arts levels.

#Mindview 6 lean sigma how to#

A LSS certification helps individuals know how to take advantage of both systems to improve their organization’s efficiency and reduce waste. However, individuals certified in both protocols through LSS certification can maximize the benefits. Six Sigma and Lean certifications are valuable in their own rights - individuals certified in these strategies can assist companies in implementing these methods throughout their organizations. While there is no standard for earning certification, certification courses require that individuals have practical experience and attend training courses.

#Mindview 6 lean sigma professional#

LSS certification indicates that a person has been trained in both Six Sigma and Lean protocols through an organization that offers certification, such as universities, companies and professional associations. You can reach various Lean certification levels to display your competency. Since many leading manufacturing organizations synthesize Six Sigma and Lean Manufacturing practices to receive the benefits of each system, people may want to earn a certification displaying their competency in both of them. Additionally, Lean certification is respected as a professional credential globally and across industries. Lean certification validates a person’s experience and knowledge of Lean principles. Any steps a customer wouldn’t pay for are removed to ensure your production processes are profitable and efficient.

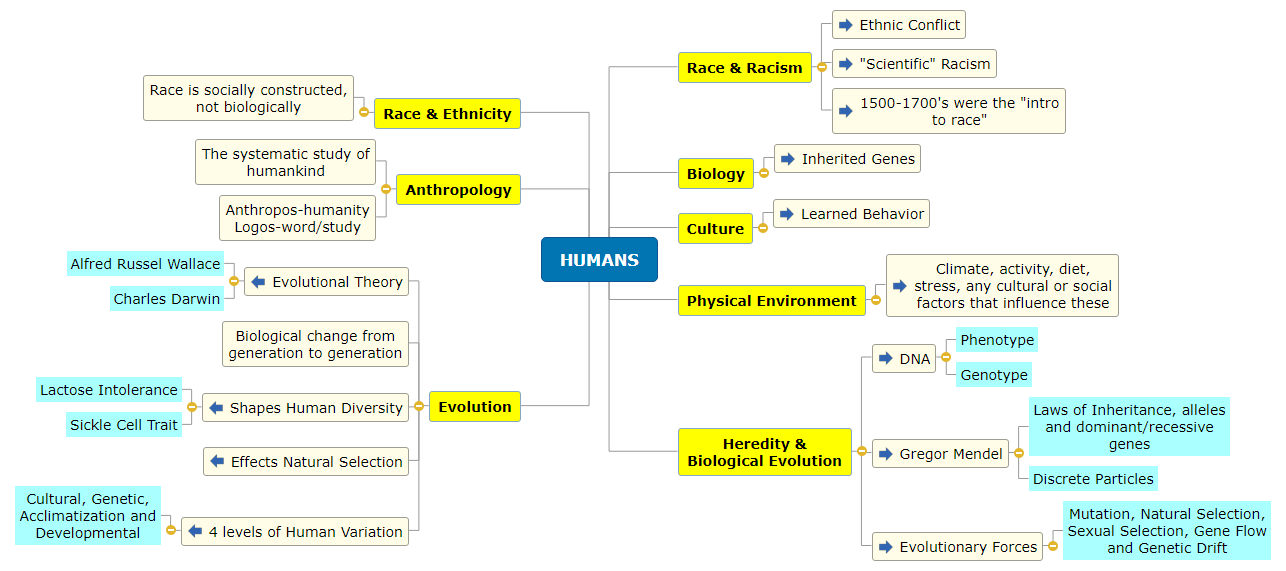

Lean methodology examines whether a step provides something to the product that a customer would pay for, and this determines what adds value. In this system, a company attempts to reduce steps to only those adding value to the product. While Six Sigma focuses on eliminating defects and waste to produce near-flawless products, Lean emphasizes cutting wasteful and unnecessary steps during a product’s creation. While the concept was initially designed for manufacturing, companies found it can apply to every part of their operations, such as attempting to reach near-perfect results for deliveries and customer support. Six Sigma ultimately uses data to produce products and results that are as perfect as possible since defective items lead to waste. Six Sigma improves on all business processes by eliminating waste and defects. The term “Six Sigma” refers to statistical quality control. Though they have their similarities, any company looking to take advantage of either should know how they differ. Adding to the confusion, many companies use them together to achieve the best results. People often confuse the two as both systems strive to achieve the same goal of streamlining production and processes. To understand how LSS works, it’s first important to know that Six Sigma and Lean are two different systems. Here, we will discuss LSS certification in detail, along with the certification levels associated with this standardization system.

Individuals with a Lean Six Sigma (LSS) certification are especially valuable in the manufacturing sector, as certified employees know to use both systems to best effect. These systems accomplish these goals differently, with some companies using them both to take their businesses to the next level. Though Lean and Six Sigma employ different methods, they both aim to reduce waste and improve a business’s efficiency. Lean and Six Sigma are two of the most valuable systems to streamline key business processes in the manufacturing industry.

0 kommentar(er)

0 kommentar(er)